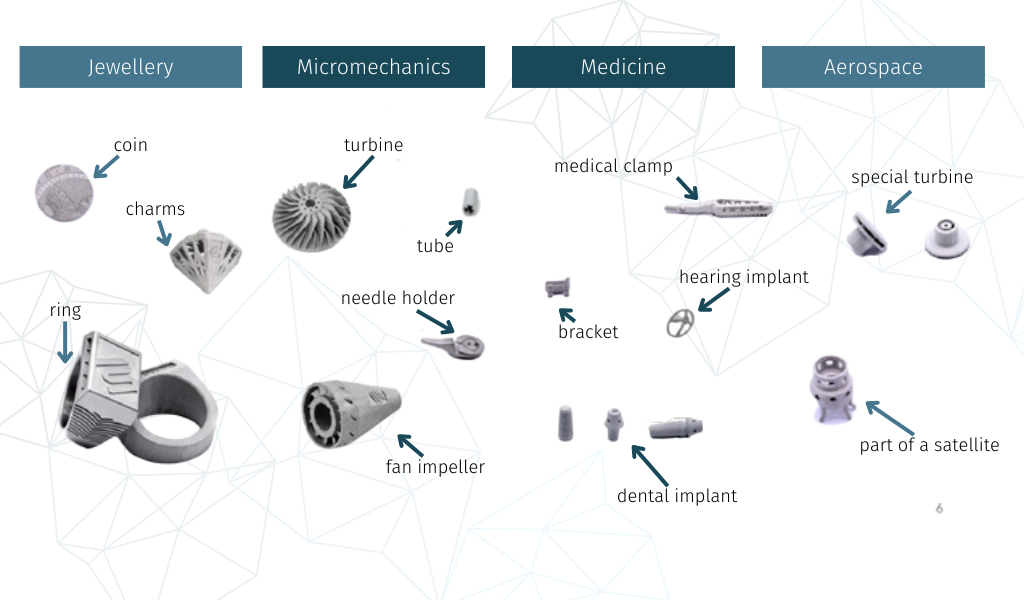

Micro-parts

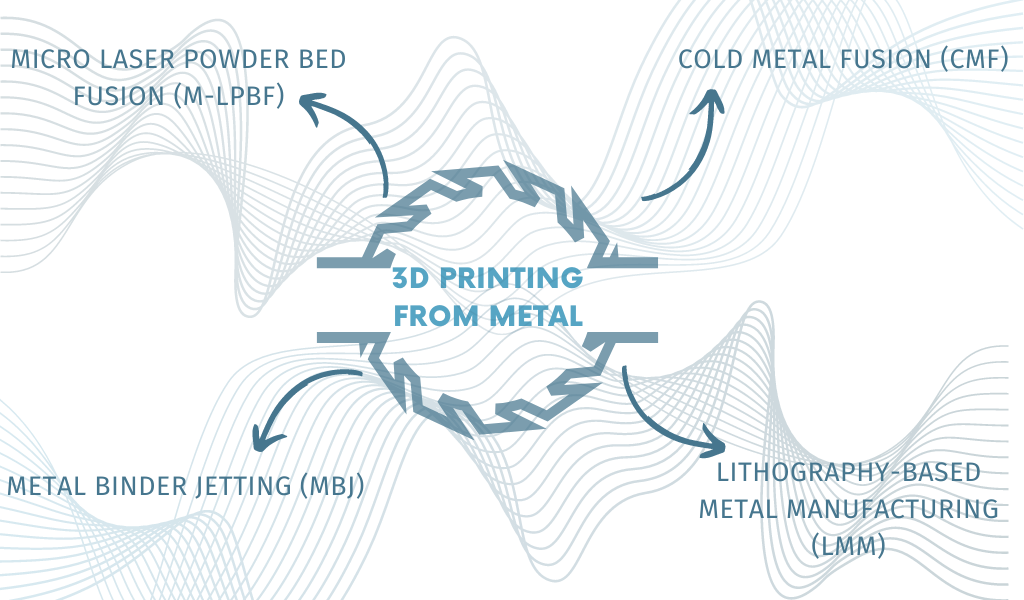

They can be manufactured using several 3D printing technologies. You should familiarize yourself with each of them to make the best choice.

These methods can be divided into direct and indirect methods. Direct methods are characterized by a one-step production process. They have the advantage of fast production time and high repeatability. However, they consume a great deal of heat, and the parts produced in this way have a welded structure. As for indirect methods, they are based on a two-step production process. They have the advantage of high productivity and quality control of manufactured parts (thanks to post-printing processing). However, the process chain is complicated, as well as subject to the risk of shrinkage.

Technologies that allow metal printing

Micro Laser Powder Bed Fusion (M-LPBF)

Micro Laser Powder Bed Fusion (M-LPBF) is an advanced 3D printing technology that uses a laser to melt and fuse metal particles to create three-dimensional objects. M-LPBF is one type of direct technology.

The M-LPBF process begins with the preparation of a 3D model, which is then sent to a 3D printer. This printer uses an intermediate layer, which is coated with a thin layer of metal powder. A laser is then directed at the surface of this layer, melting and fusing the metal particles where they are needed to create the 3D model. Subsequently, the printing platform is lowered by a few microns, and another layer of metal powder is evenly spread on top. The printing process is repeated, layer by layer, until the object is complete.

M-LPBF has several advantages over other 3D printing technologies. It allows the creation of parts with very precise shapes and high surface quality. By using a high-powered, high-accuracy laser, M-LPBF is ideal for printing small, complex parts with high dimensional precision and tolerances. It is also relatively faster compared to other 3D printing technologies, making it an ideal choice for small batch or prototype production. However, it is an expensive technology and requires specialized knowledge and skills to operate it properly.

Cold Metal Fusion (CMF)

Cold Metal Fusion (CMF) is a 3D printing technology that uses metal powder and a special printing machine to produce 3D models. It is an intermediate technology.

The CMF printing process begins with the preparation of a 3D model, which is then sent to a 3D printer. The printer has a print head that sprays a thin layer of metal powder onto a flat substrate. Then, using a laser or other energy, the metal powder is fused at specific locations to create the 3D model. After the first layer is fixed, the substrate is lowered by a small distance, and another layer of metal powder is evenly spread over the previous layer. The printing process is repeated, layer by layer, until a complete 3D model is achieved.

CMF has several advantages over other 3D printing technologies. It is a fast and precise 3D printing method that allows for the creation of models with very high surface quality and dimensional accuracy. In addition, CMF is relatively inexpensive and easy to operate, making it ideal for companies and individuals looking to produce low to medium runs of metal parts. However, the printing process is sensitive to temperature and humidity changes, which can affect the quality and accuracy of the 3D model.

Lithography-based Metal Manufacturing (LMM)

Lithography-based Metal Manufacturing (LMM) is another name for a 3D printing technology also called Direct Metal Writing (DMW), which uses a photolithographic process to produce 3D models from metal. It is a direct technology, meaning that the model is printed directly from the starting material.

The LMM printing process begins with the preparation of a 3D model on a computer. This model is then sent to a 3D printer, which has a special print head. The head contains metal powder, which is evenly distributed on a flat surface, called a printing table. Once the powder is distributed, the print head emits UV light, which cures the powder where it is needed to form the first layer of the 3D model. Once the first layer is cured, the printing table lowers by a small distance, and another layer of metal powder is evenly spread over the previous layer. The printing process is repeated, layer by layer, until a complete 3D model is achieved.

LMM has several advantages over other 3D printing technologies. It is a fast and precise 3D printing method that allows for the creation of models with very high surface quality and dimensional accuracy. In addition, LMM is relatively inexpensive and easy to operate, making it ideal for companies and individuals looking to produce low to medium runs of metal

Metal Binder Jetting (MBJ)

Metal Binder Jetting (MBJ) is one of the incremental technologies used to produce three-dimensional models from metal. MBJ is an intermediate technology.

The MBJ printing process begins with the preparation of a 3D model on a computer. This model is then sent to a 3D printer, which has a special print head. This head contains metal powder, which is evenly distributed on a flat surface, called a printing table. Once the powder is distributed, the print head emits glue droplets that bind the powder where it is needed to form the first layer of the 3D model. After the first layer is fixed, the printing table is lowered by a small distance, and another layer of metal powder and glue is evenly spread over the previous layer. The printing process is repeated, layer by layer, until the 3D model is complete.

Once the model is printed, it is subjected to a sintering process, which involves heating the metal powder in a furnace to a temperature at which the powder particles gradually fuse to form a uniform metal part. As a result of this process, the printed part acquires its final form and physical properties.

MBJ has several advantages over other 3D printing technologies. It is a fast and accurate 3D printing method that allows for the creation of models with very high surface quality and dimensional accuracy. In addition, MBJ is relatively t

METShape

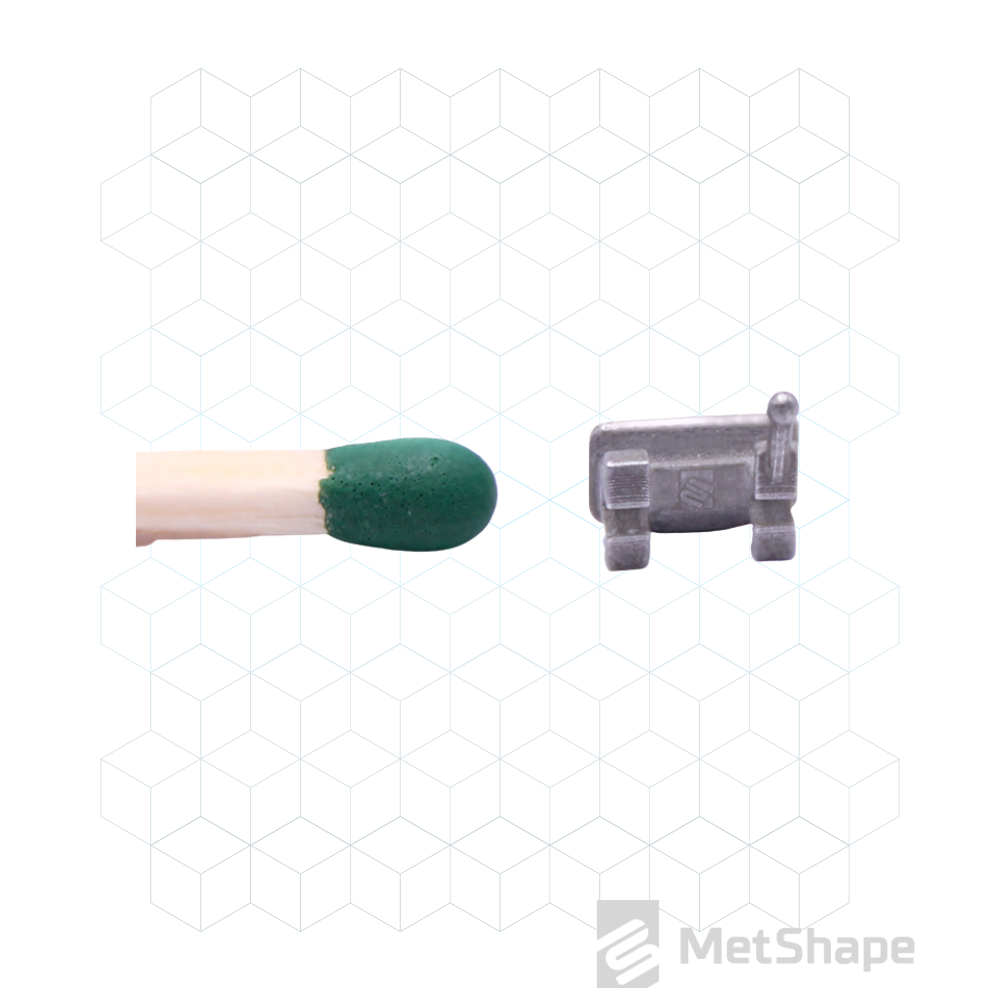

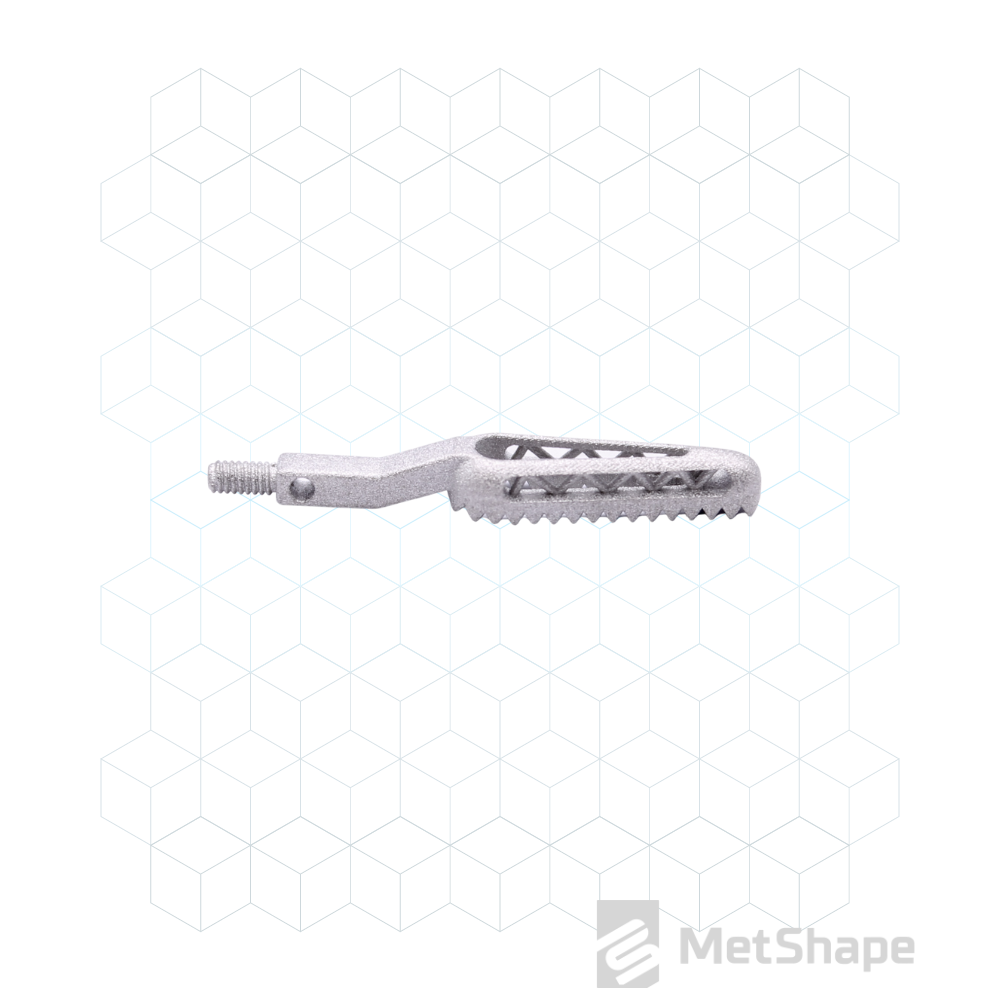

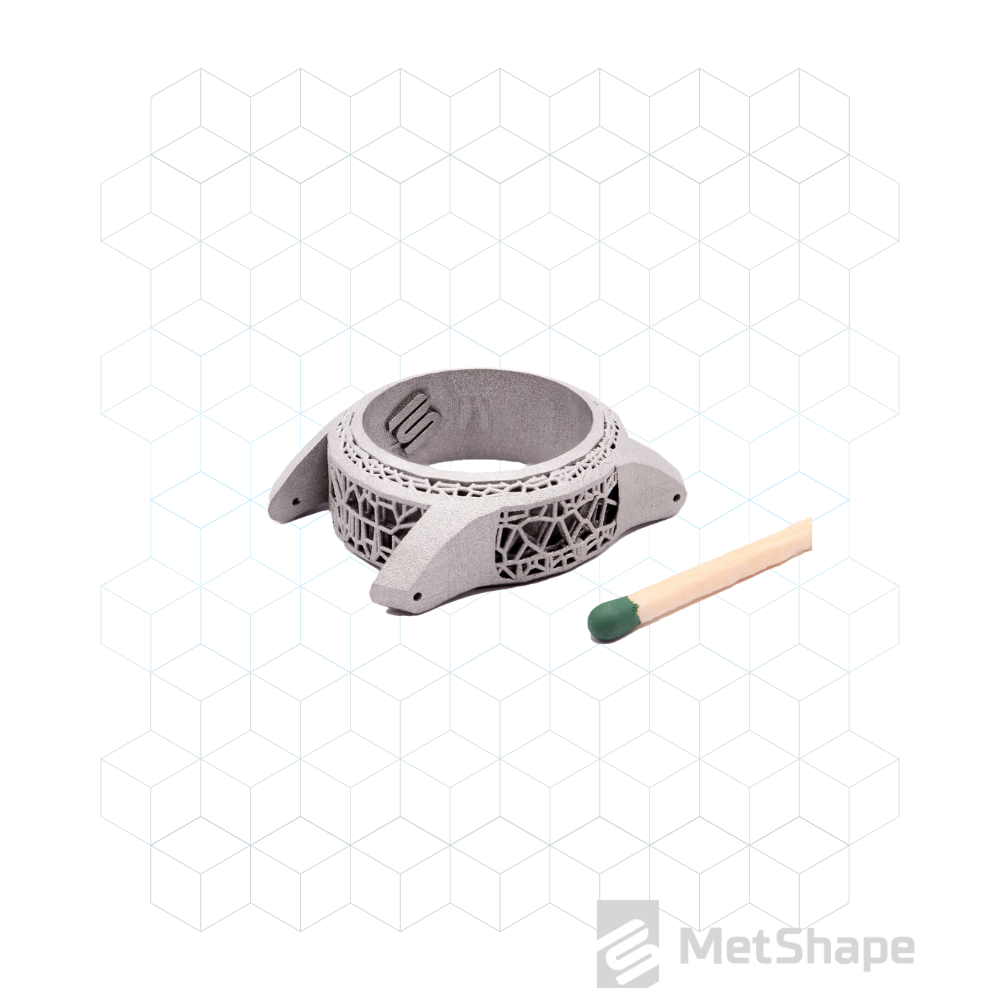

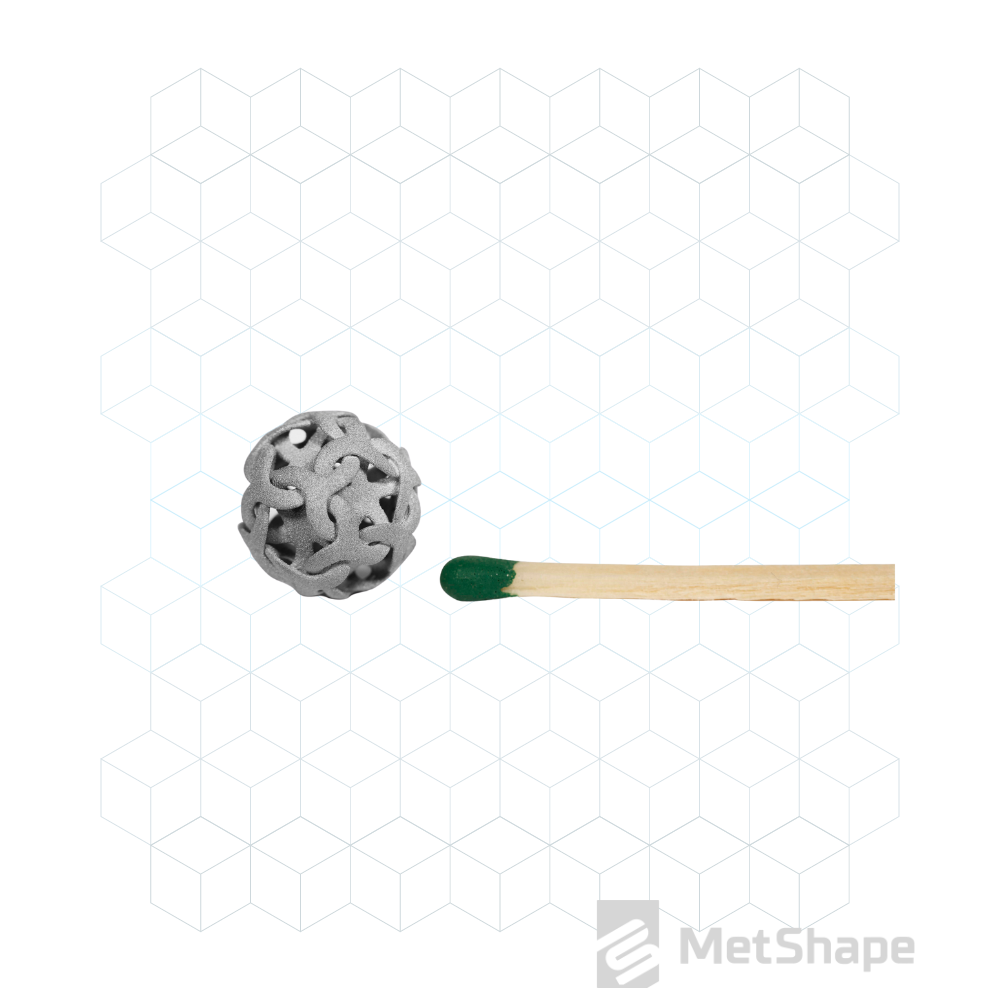

METShape is 3D Center’s partner for 3D metal printing. The company specializes in additive manufacturing based on sintered small and micro metal parts. It was founded and spun off from Pforzheim University in 2019. The idea to found the technology start-up came from a research project on rare earth magnet recycling, which developed Lithography-based Metal Manufacturing (LMM) technology. The technology makes it possible to print high-precision metal parts with an exceptionally good surface finish. In the meantime, MetShape has developed unique process know-how and focused primarily on the sintering process, so that it offers services in addition to manufacturing parts using LMM technology.

Thanks to its unique sintering know-how, MetShape offers high-quality, finished components that can be used in batch applications, compared to other 3D printing service providers that specialize in prototypes and single part production. In addition, MetShape offers its customers who use other sinter-based additive manufacturing technologies the ability to sinter their parts at high quality.

To learn more about their business and micro-part printing capabilities, we encourage you to read their brochure, which can be downloaded here.

Interested? Feel free to contact us!