3D printing technology is revolutionizing manufacturing methods, and one of the most popular methods is L-PBF (Laser Powder Bed Fusion) 3D printing. L-PBF enables the creation of durable and precise parts from a variety of metals. It allows the production of custom prototypes, complex parts and final products in a wide range of industries. Why is L-PBF technology so popular? Learn more about this fascinating 3D printing method.

What is L-PBF 3D printing technology?

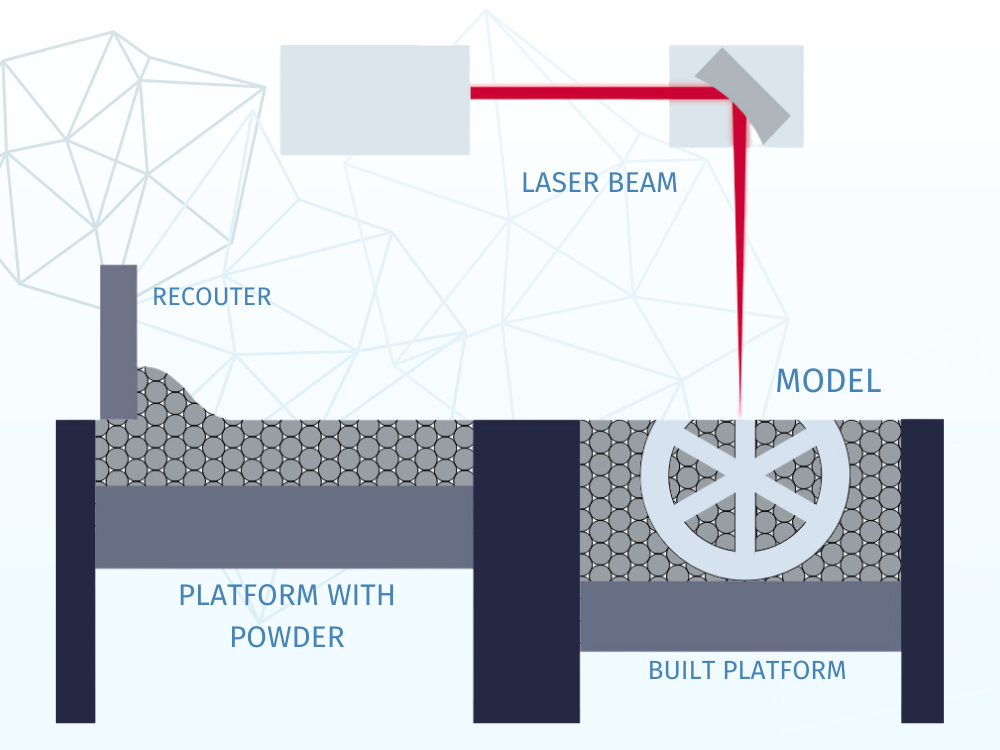

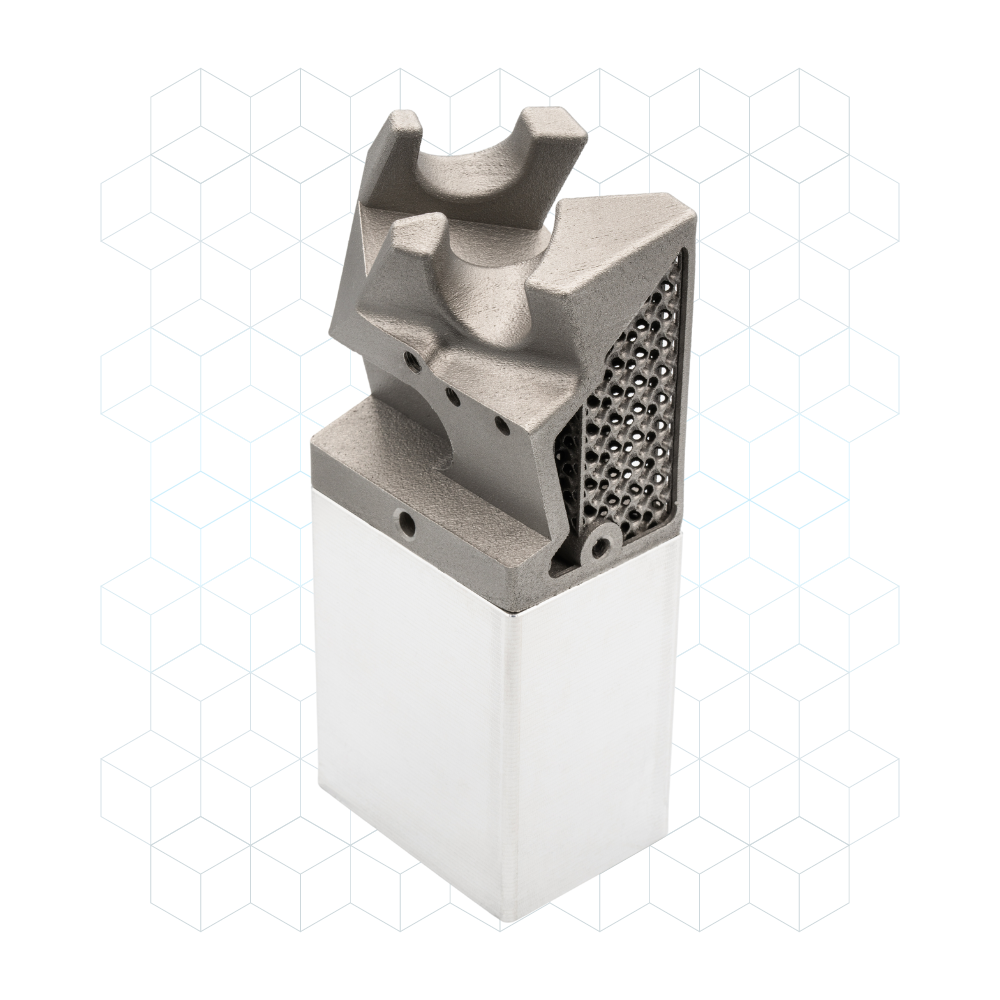

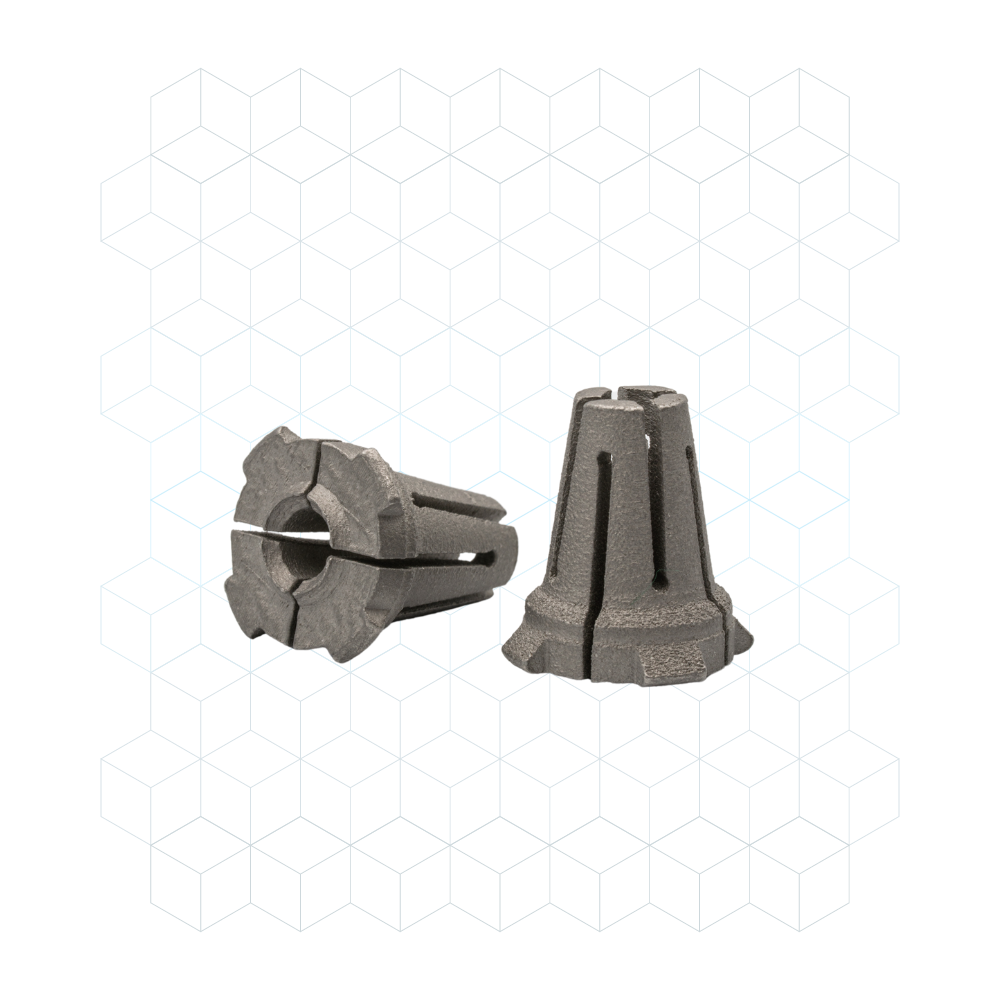

L-PBF, or Laser Powder Bed Fusion, is an advanced 3D printing method in which an object is created layer by layer by sintering or curing a powder material using a laser. This process provides exceptional precision and accuracy, making L-PBF ideal for advanced applications.

Applications

L-PBF technology is widely used in various industries such as:

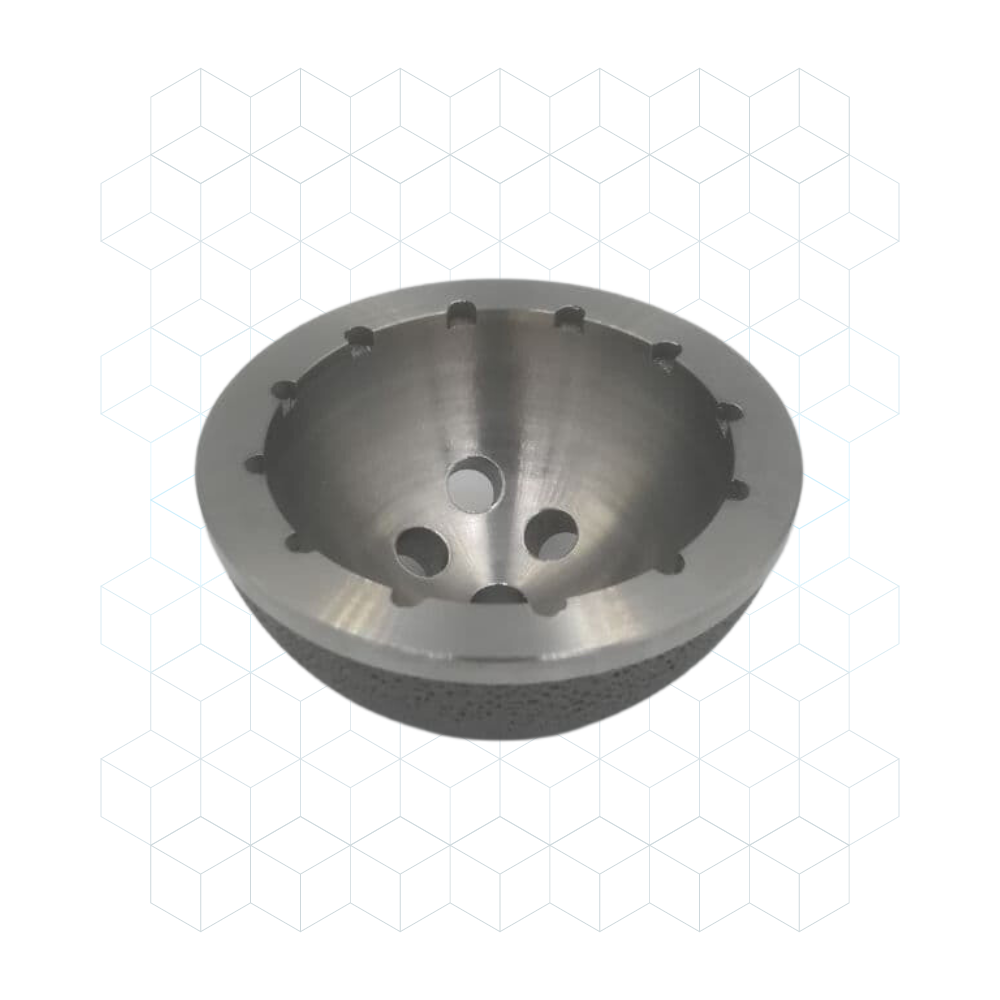

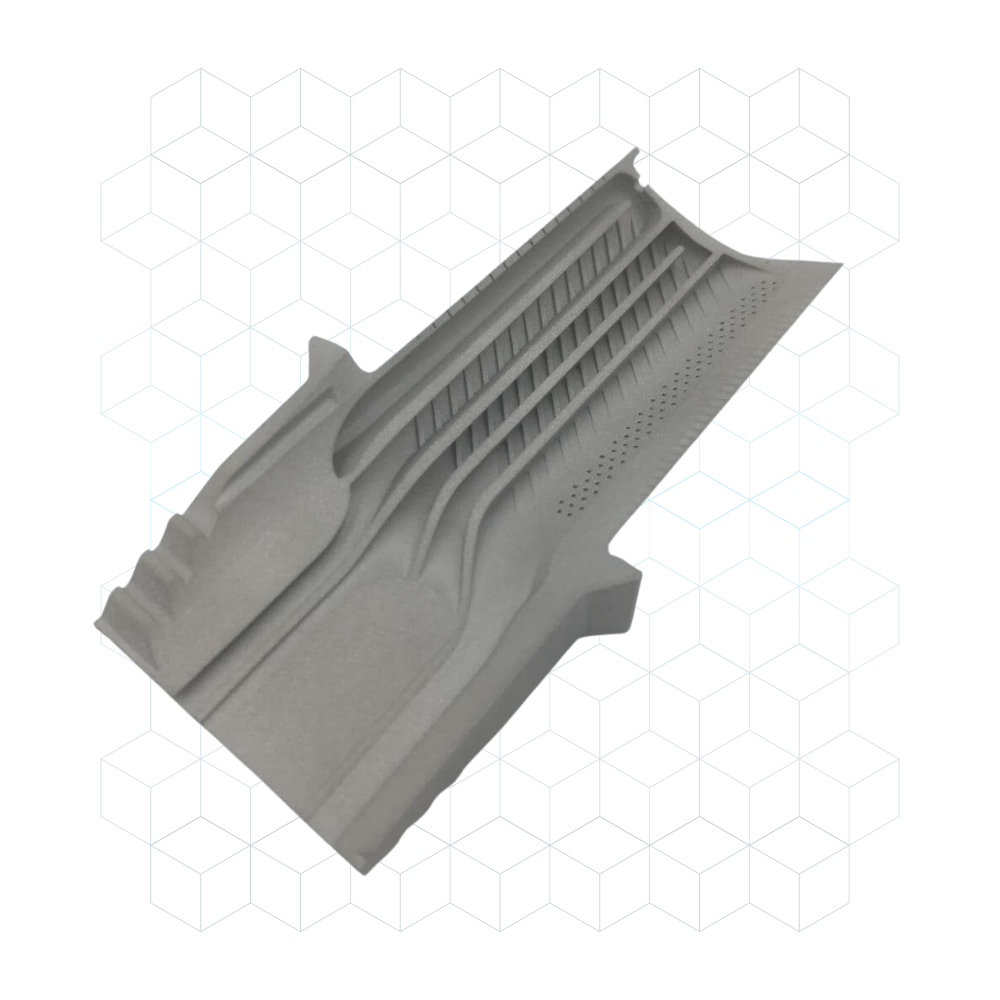

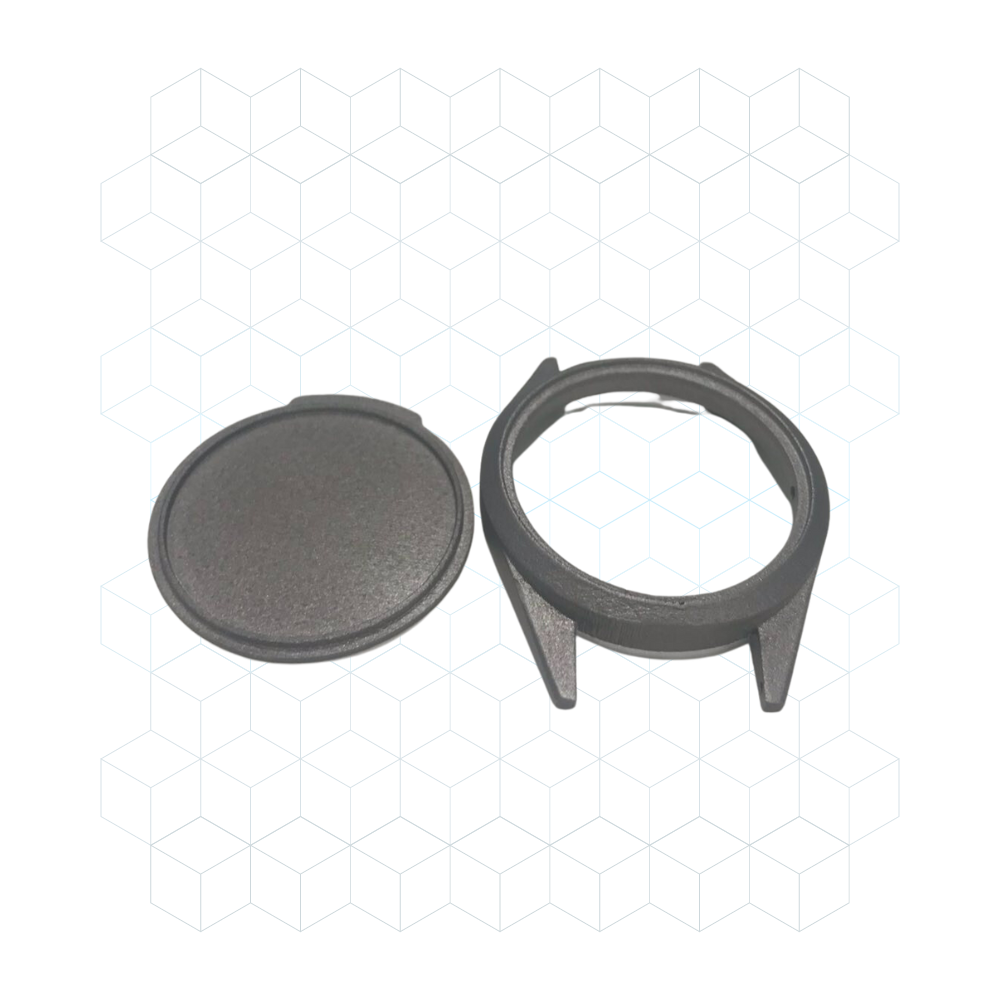

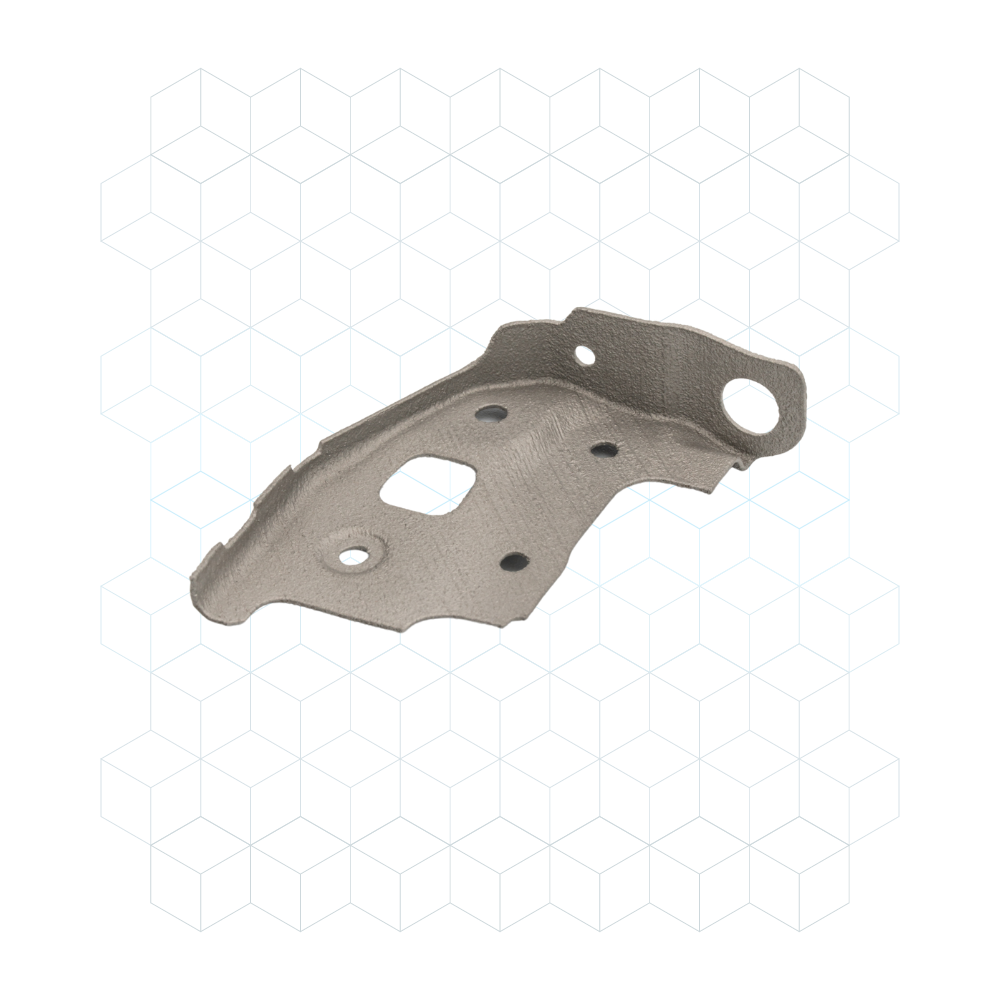

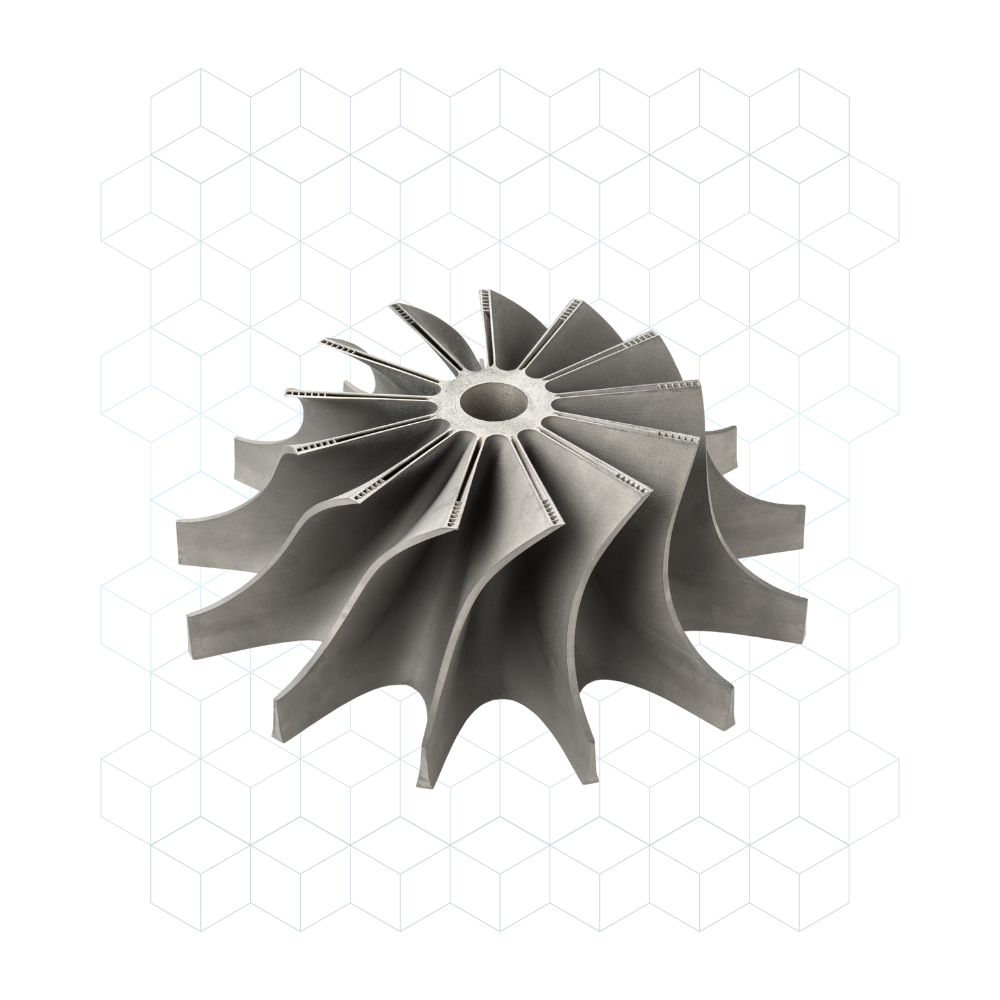

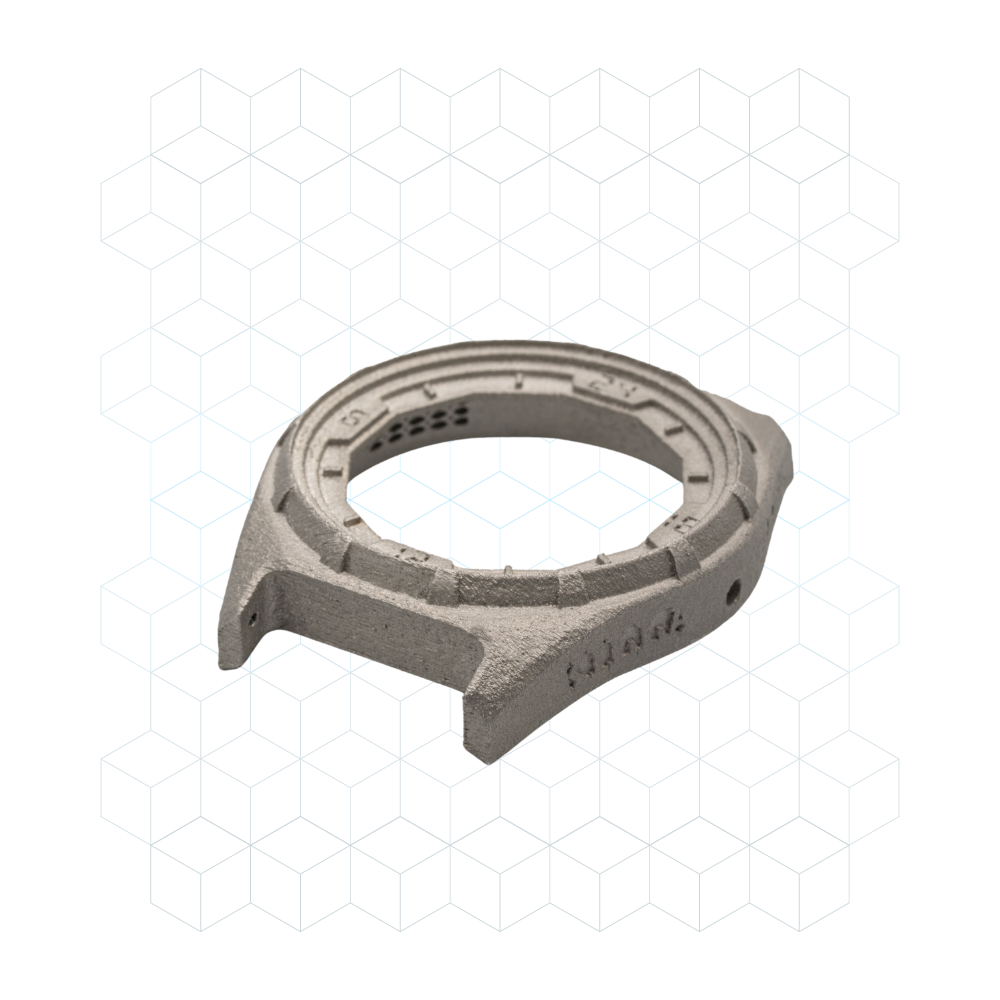

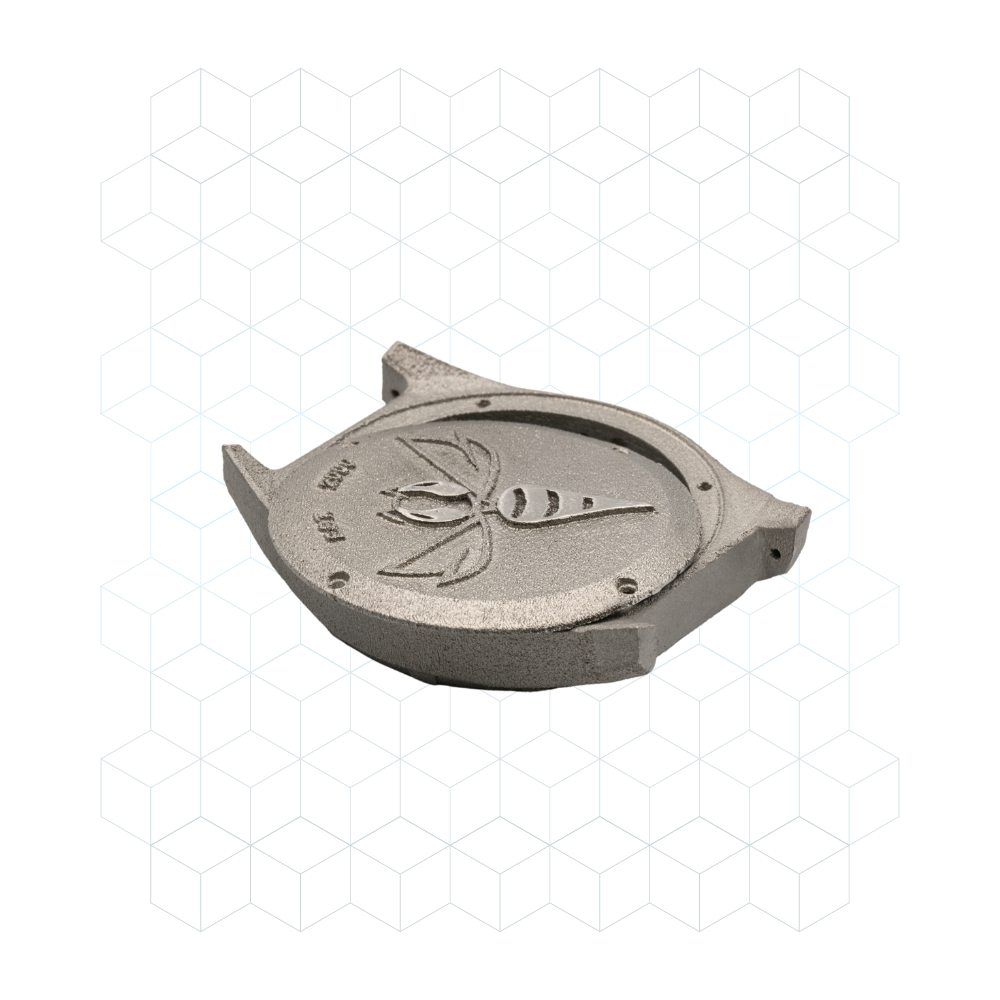

- Aerospace: L-PBF 3D printing enables the production of lightweight, robust and complex parts for engines, housings, fuel systems and other aerospace components.

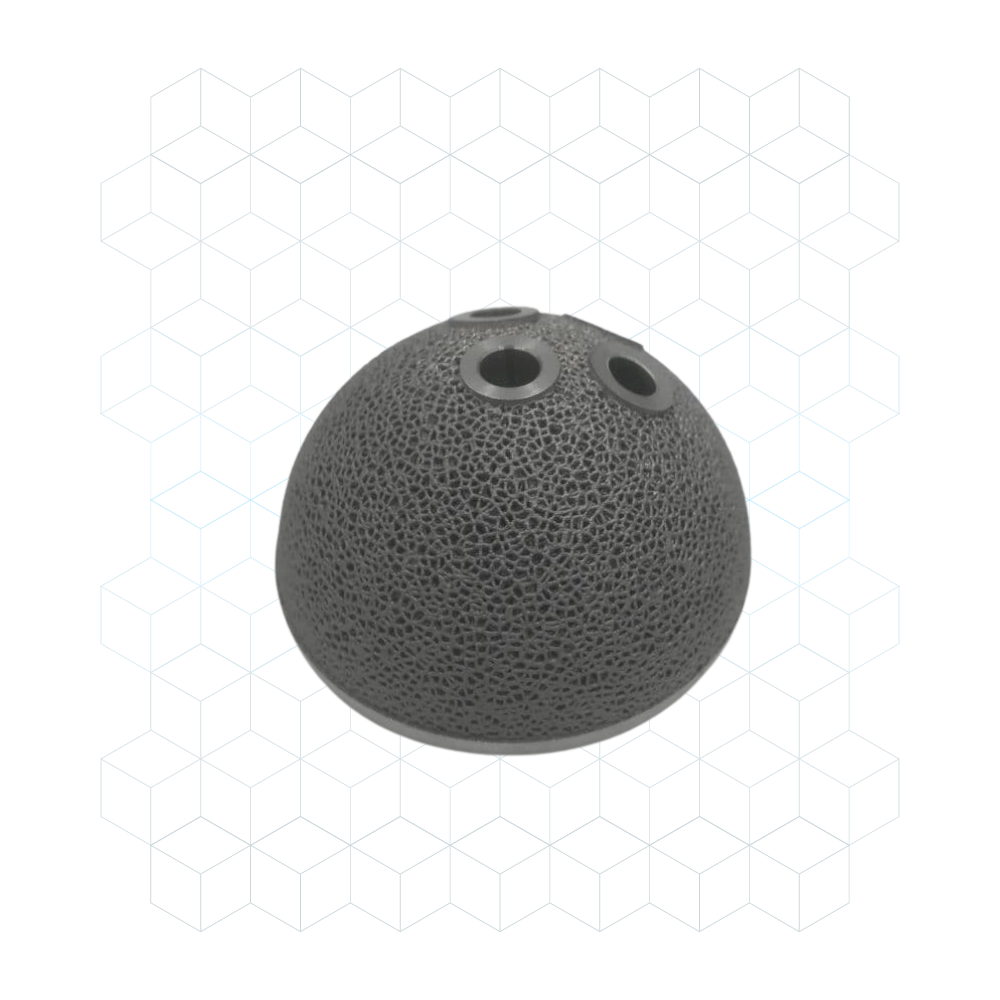

- Medical: L-PBF enables the creation of implants, prosthetics, surgical instruments and other high-precision medical components.

- Automotive: L-PBF 3D printing is used to produce customized automotive parts, exhaust systems, turbochargers and other components.