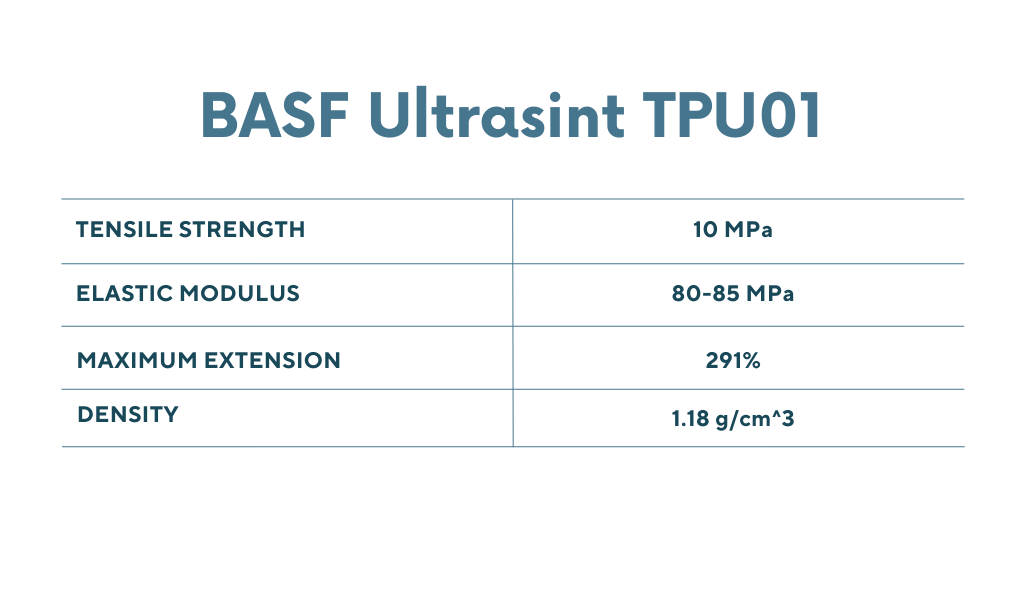

HP 3D High Reusability PA 12

This material is characterized by high strength, abrasion resistance and flexibility. It is most commonly used for parts with complex geometries and requiring high strength. In addition, it is certified for biocompatibility and meets Food and Drug Administration (FDA) requirements for materials intended for contact with intact skin. The mechanical properties of Nylon PA12 are shown in the table opposite.

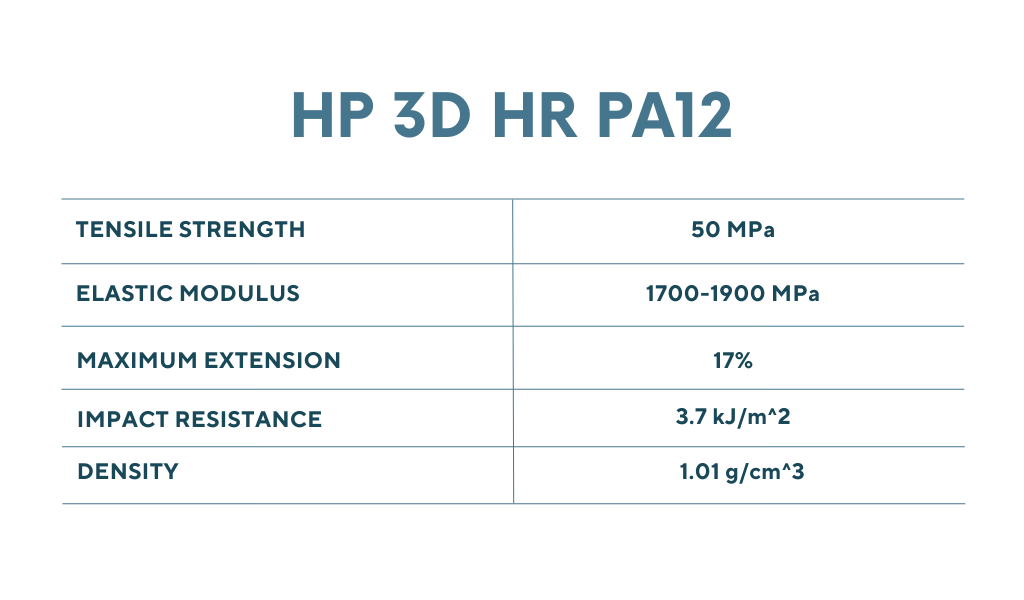

HP 3D High Reusability PA 12 Glass Beads

It is a glass fiber reinforced nylon PA12. It contains 40% glass beads in its composition. The addition of glass beads increases the stiffness of the material and its mechanical strength. It is best suited for parts requiring high stiffness and bending resistance.

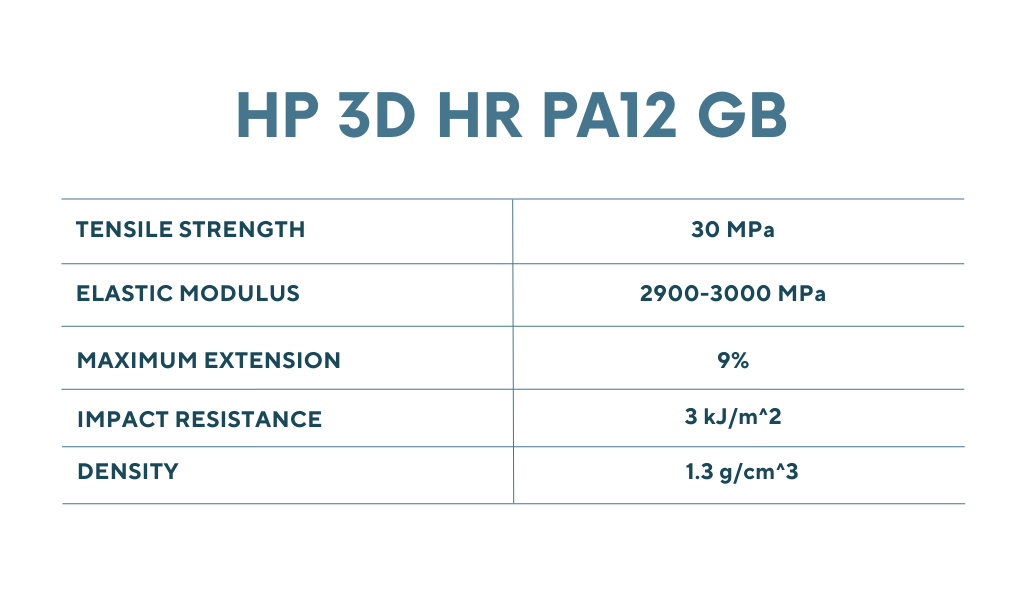

HP 3D High Reusability PA 11

It is a lower density and more flexible material than PA12. It shows very good resistance to chemical agents. It is used where the requirement for the material is high impact strength and high ductility, e.g.: shoe insoles.

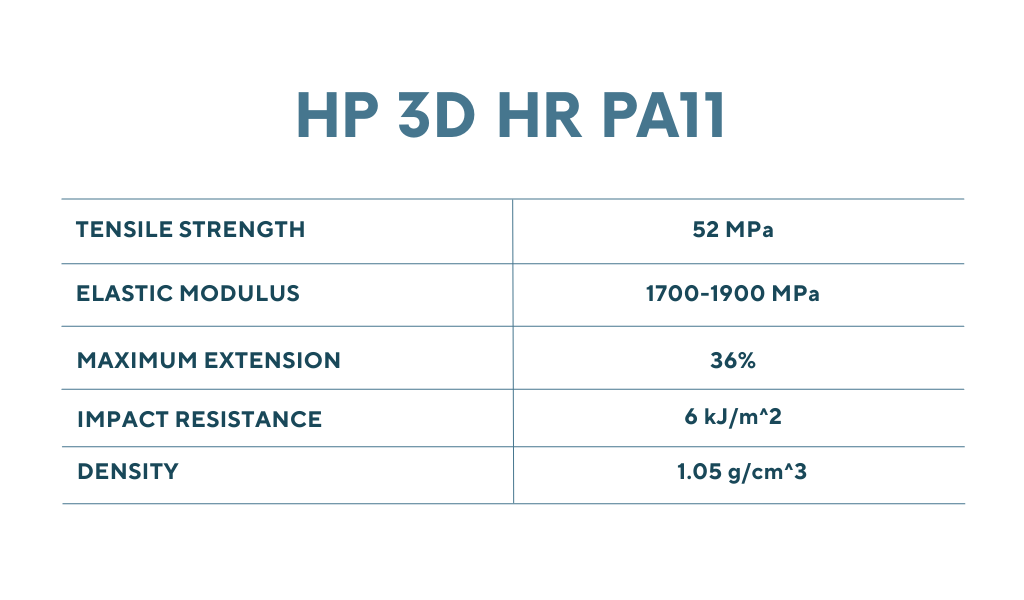

BASF Ultrasint® TPU01

This is the most flexible material used in Multi Jet Fusion HP technology. It exhibits resistance to oils, fats and chemicals. In addition, it is characterized by high bending resistance. It is used to produce parts for cushioning and parts that require high breaking strength.