Just provide us with photos and dimensions of the model or the part itself. We will make the model for you!

Depending on the complexity of the model, we offer both conventional modelling and 3D scanning technology. Our 3D models are optimised for the additive technology (3D printing), the respective application, the price or the required production process of the specific part/product. With a 3D model you can make any part in any number on demand in a very short time. Don’t keep a stock of spare parts, format parts or maintenance parts. Create your own virtual warehouse and produce only as many as you need. Save resources, space and add a contribution to environmental protection.

What is it?

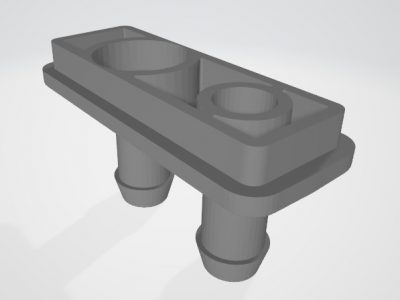

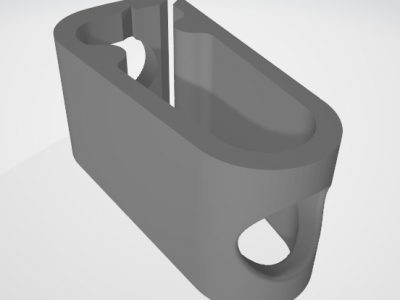

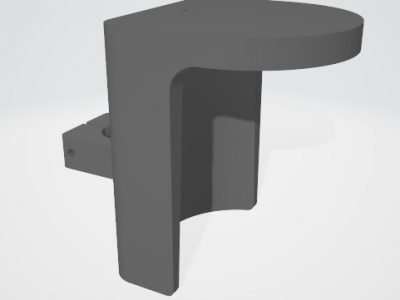

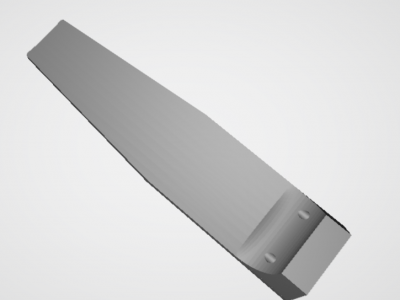

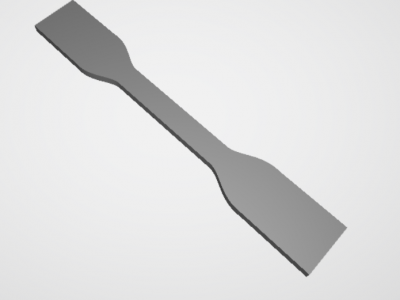

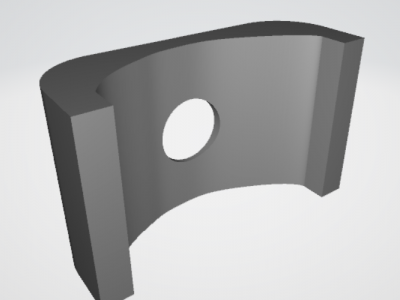

3D modelling

3D modelling is the process of creating a 3D model. With its help, almost any object or surface can be digitally represented as required. Special CAD software is used for this purpose. Models can be created from simple solids such as a cube, cone or sphere. A model can also be created using sketches, which can then be drawn to the intended shapes. What this looks like in a nutshell can be seen in the video opposite.

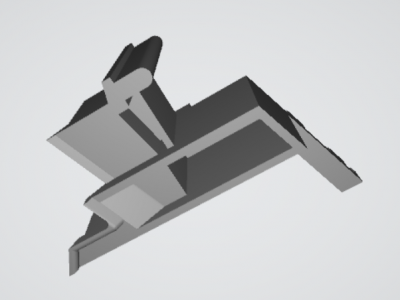

3D scanning

3D scanning is done using a 3D scanner. The scanner creates a 3D model (using a point cloud) based on the physical object. Most often, after scanning, the files are in STL format, which can be further worked on (for example, adding unscanned surfaces or modifying those that have been successfully scanned). Scanners allow an accuracy of up to 0.005 mm, so they are ideal for the need to model very complex surfaces. Depending on the type of scanner, very small things can be scanned, as well as huge things (even entire buildings or rooms).

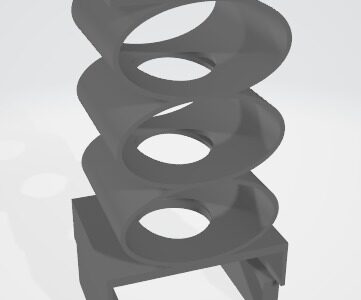

Optimisation

Topology optimisation is the process of optimising parts or tools. It is usually done by reducing the material needed for manufacturing. For example, where there are no large forces acting on the model, an openwork surface can often be used, which significantly reduces the volume of the model and the amount of material needed to manufacture it. In optimisation, the most important thing is to make the part as efficient as possible with as little volume as possible. The key here is to lay out the geometry in such a way that, at low mass, it can still carry the same loads as a solid structure.

Virtual warehouse

With 3D modelling, it is possible to create a so-called virtual warehouse. This enables parts to be modified more quickly, for example production line components. Thanks to the 3D model database, geometries can be modified easily. It is no longer necessary to store piles of technical documentation.