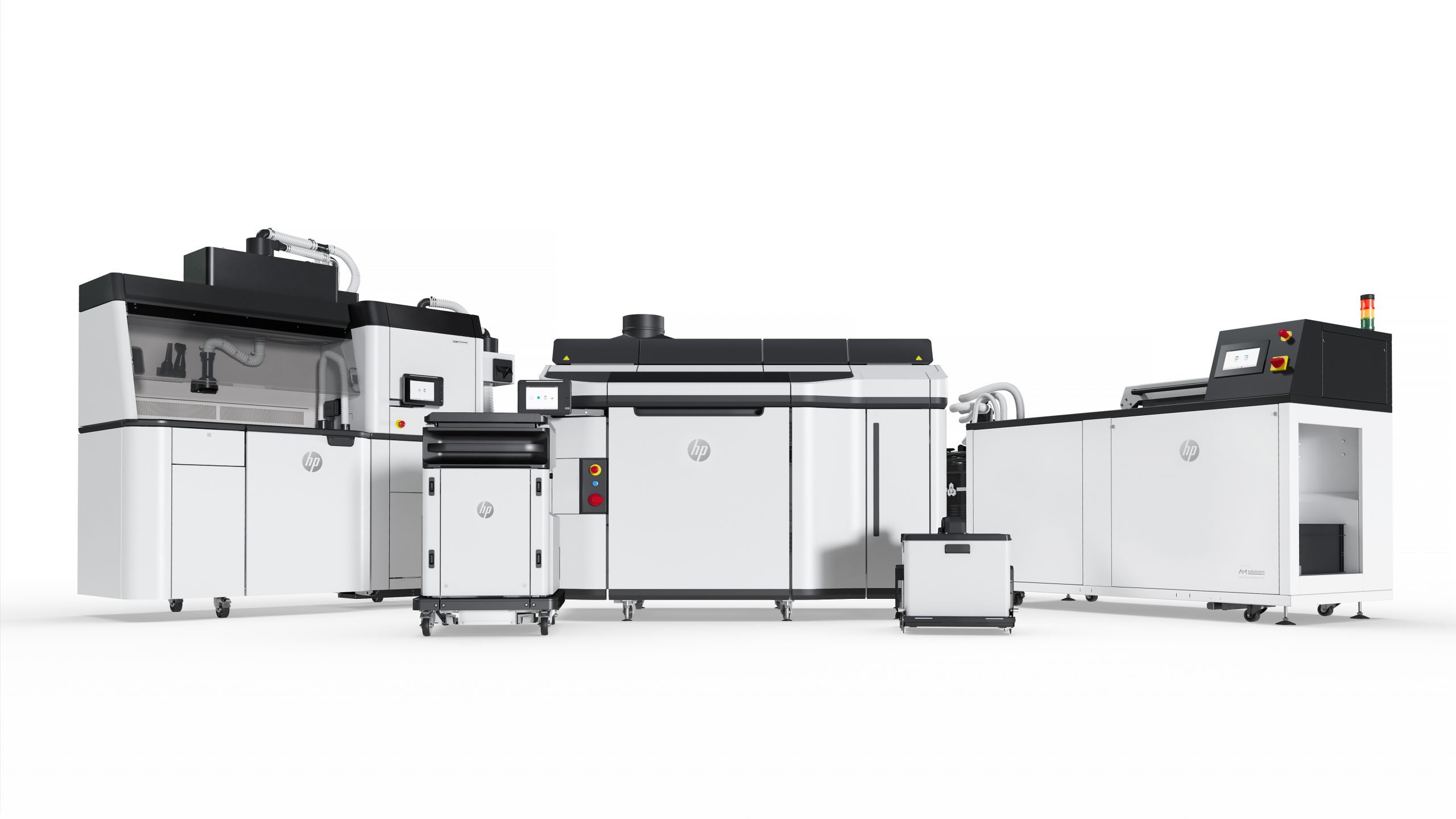

HP Multi Jet Fusion

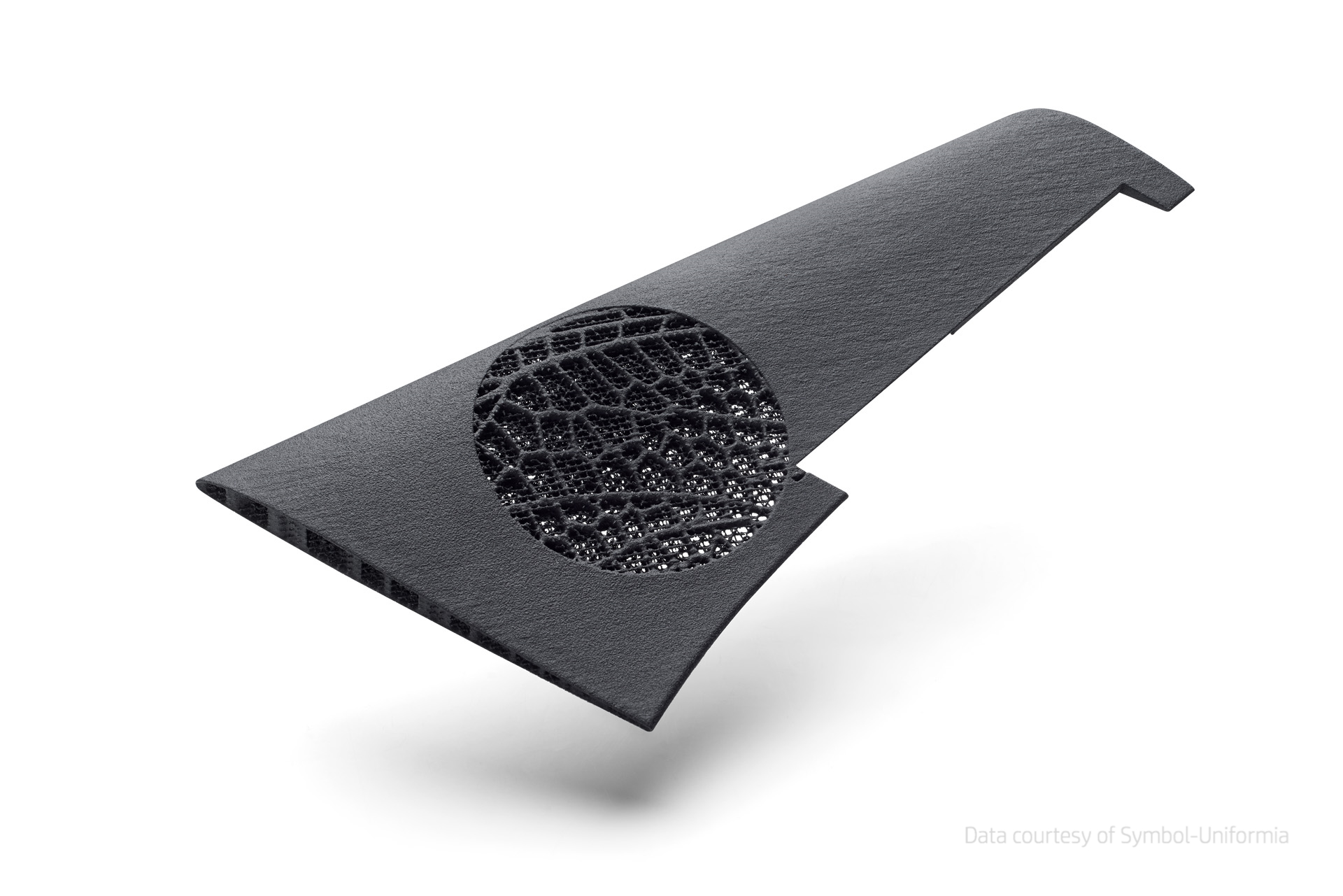

HP Multi Jet Fusion (MJF) technology is an advanced 3D printing method that enables the creation of highly precise and durable plastic objects. The technology was developed by HP and will surpass other technologies due to its speed, quality and efficiency.

In a nutshell, the MJF printing process is based on applying thin layers of powder to a platform. Then, the print heads apply dedicated chemicals – agents (fusing and detaling) to the surface of the powder, which is then melted using a UV lamp. The powder, which has been heated and the energy absorption has been enhanced by fusing, forms a homogeneous structure, resulting in robust and precise objects. MJF technology offers a number of advantages, including highly precise and durable prints, high printing speeds and the ability to print in large batches. In addition, with post-processing capabilities, even better surface quality and detail can be achieved.

MJF technology can use a wide variety of plastics, such as nylon, polypropylene and polyurethane, allowing the creation of a variety of objects with different mechanical and thermal properties.

![Drukarka przymysłowa do druku 3d [zamknięta] HP MJF druk 3d](https://3dcenterpolska.pl/wp-content/uploads/2022/12/Crait-Front_203_v1b-scaled.jpg)

![Drukarka przymysłowa do druku 3d [otwarta] HP MJF druk 3d](https://3dcenterpolska.pl/wp-content/uploads/2022/12/Crait-Front_208_v1b-scaled.jpg)