In the ever-evolving world of technology, there are times when...

Read MoreA New Era of Machine Part Production

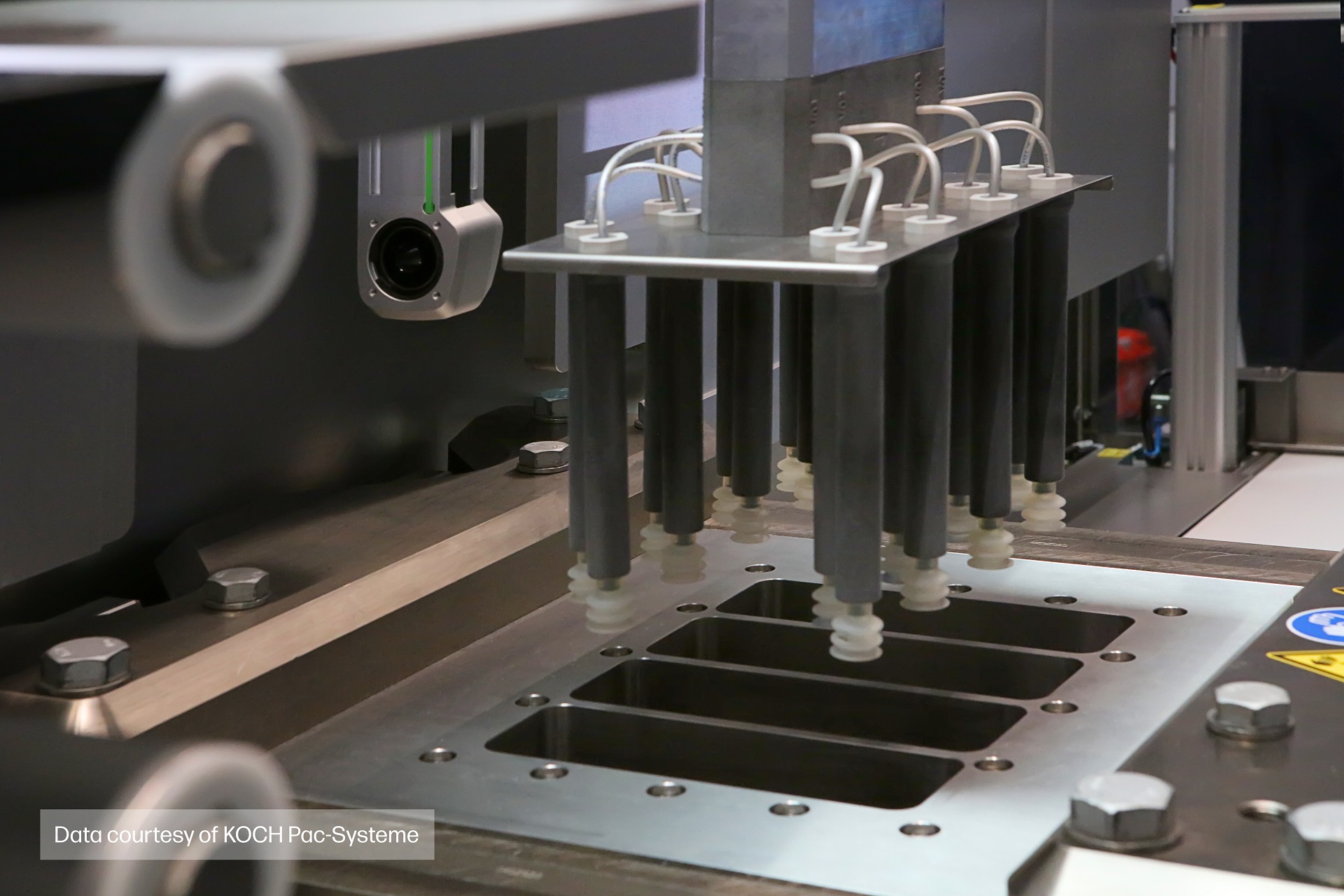

In today’s industrial world, companies involved in the production of packaging machines and production lines are constantly seeking innovative solutions to enable faster production, lower costs, and higher-quality parts. 3D printing, particularly with HP Multi Jet Fusion (MJF) technology, is one such solution that is revolutionizing the manufacturing of machine parts for packaging.

Benefits of 3D Printing in Packaging Machine Production

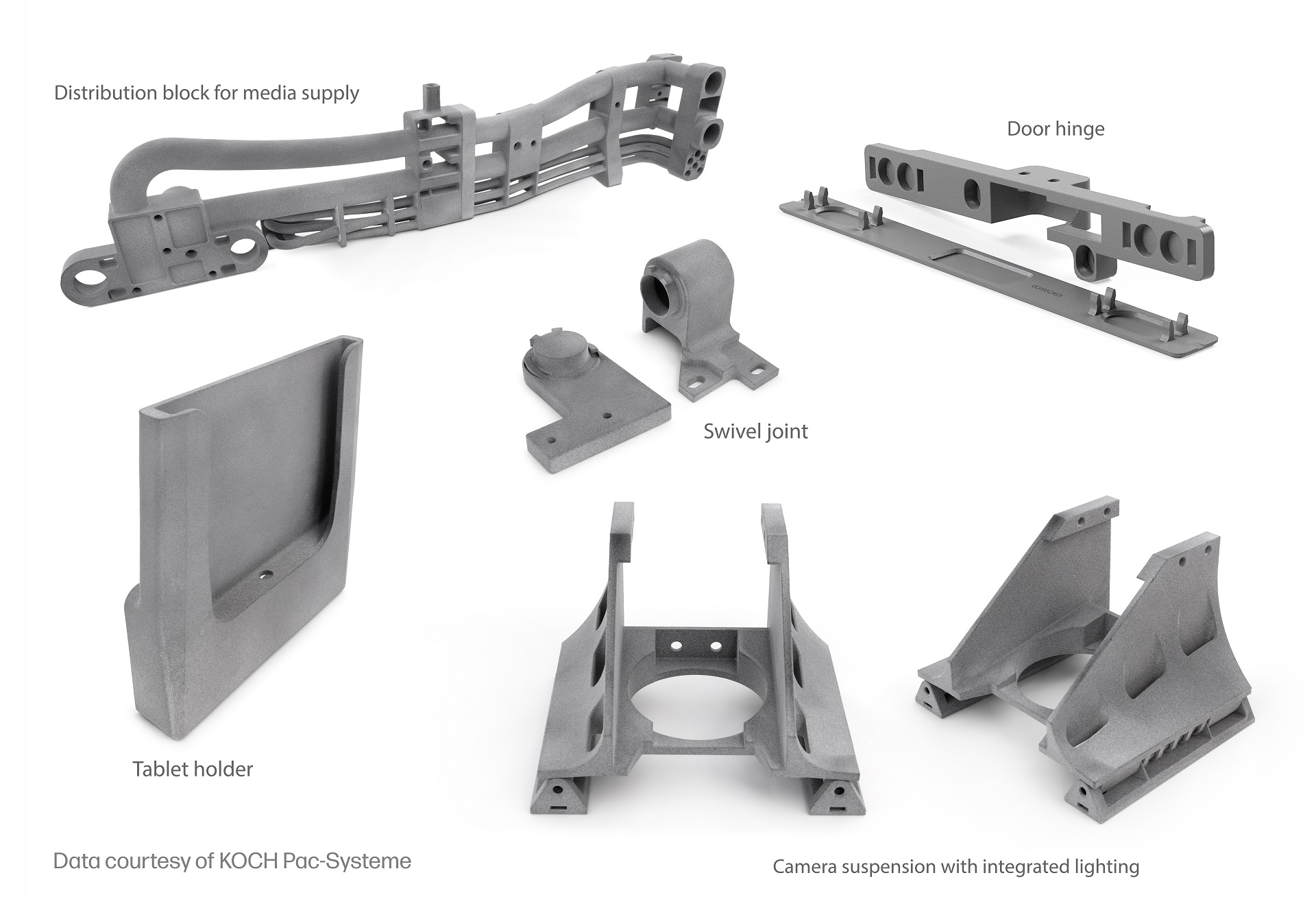

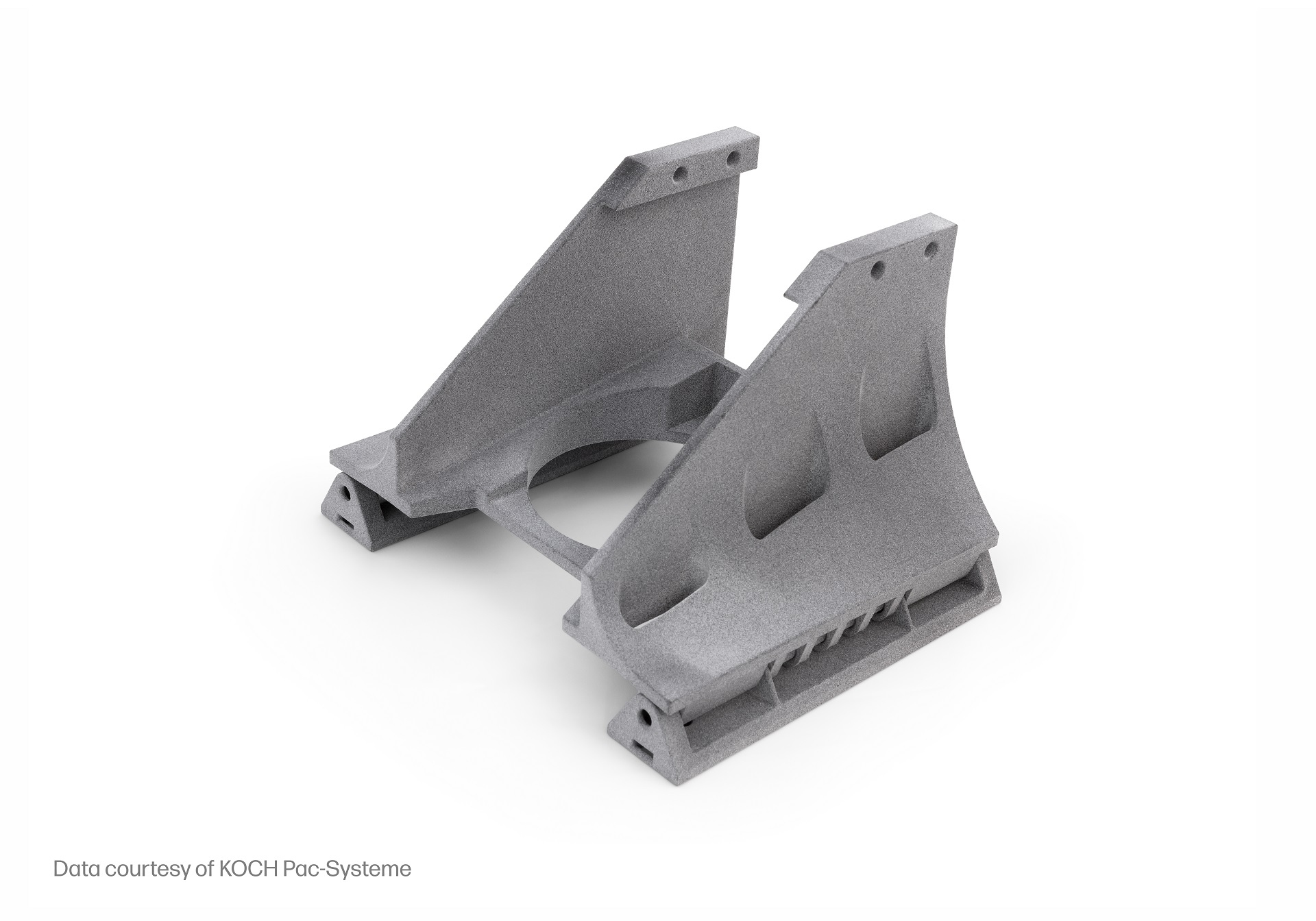

KOCH Pac-Systeme, a leader in the market for packaging machines, blisters, and cartoning, has successfully implemented HP 3D printing technology in its production. Thanks to this technology, they have been able to create more complex, lighter, and simultaneously more cost-effective machine parts—something impossible to achieve with traditional manufacturing methods.

3D printing in the production of packaging machines offers several advantages for companies involved in creating production lines:

- Production Costs: 3D printing significantly reduces costs compared to traditional manufacturing methods such as injection molding or machining. As a result, producing small batches of custom parts becomes more cost-effective.

- Rapid Prototyping: With 3D printing, you can quickly test designs, make modifications, and test new versions of parts in a short time. This enables faster production and reduces lead times.

- Complex Geometry: 3D printing allows for the production of parts with highly complex geometries that would be impossible to manufacture using traditional methods. The ability to create intricate shapes and structures is a huge advantage in packaging machine production.

- Sustainability: HP Multi Jet Fusion technology offers a high material reuse rate (up to 80%), leading to lower material consumption and a reduced environmental impact.

Increased Flexibility and Cost Savings

Implementing HP Multi Jet Fusion technology allows companies producing packaging machines to significantly improve production flexibility. With this technology, KOCH Pac-Systeme can create machine components faster and more efficiently.

Moreover, the ability to manufacture machine parts in low volumes on-site instead of outsourcing production to external manufacturers saves both time and money. Additionally, engineers can continuously refine and modify designs, increasing order fulfillment speed and improving customer satisfaction.

How Can 3D Printing for Production Lines and Packaging Machines Benefit Your Company?

If your company is involved in the production of packaging machines and wants to optimize manufacturing processes, 3D printing is a solution worth considering. This technology offers great flexibility in designing and manufacturing machine parts that are lighter, more complex, and cheaper to produce compared to traditional methods.

Faster Prototyping and Production

3D printing enables rapid prototyping, testing of new designs, and modifying machine parts without having to restart the entire manufacturing process. This means shorter lead times and greater customer satisfaction, as they can receive their finished products more quickly.

Conclusion: How 3D Printing Can Transform Your Packaging Machine Production

Integrating 3D printing technology into the production of packaging machines is a step toward more efficient, sustainable, and flexible manufacturing. With this technology, you can create complex and custom machine parts that are lighter, more efficient, and cheaper to produce.

If your company produces packaging machines, don’t wait any longer—embrace 3D printing to optimize production and enhance your competitiveness in the market. Contact us to learn how we can help you introduce this technological revolution into your manufacturing processes.

Filip Nowak

Może Cię też zainteresować

3D Printing in Architecture and Construction: A Revolution in the Industry

3D Printing in Architecture and Construction: A Revolution in the...

Read More