A revolution in virtual reality: Mira’s journey with Multi Jet Fusion 3D printing

In the ever-evolving world of technology, there are times when innovation intersects with human imagination. Mira, a pioneering augmented reality (AR) company, has caught the eye by seamlessly integrating Multi Jet Fusion 3D printing technology with its groundbreaking smartphone-powered augmented reality system. The result? The combination of Mira and Multi Jet Fusion technology has become an inspiring example of how cutting-edge incremental techniques can transform the AR industry.

Mira’s mission: to increase team effectiveness

Mira, the tech start-up founded by Ben Taft and Matt Stern in 2016, was quick to recognise the potential of MJF. The lightweight and affordable Mira Prism headset they presented, combined with a mobile app, turns the smartphone into a gateway to a new world of augmented reality. It is designed for enterprise employees, for whom it will become a hands-free tool to help them dynamically create reports and document information.

The 2017 Mira Prism headset.

The 2017 Mira Prism headset.

Challenge: Overcoming slow production cycles while maintaining momentum

What sets the company apart from its competitors is its great attention to user comfort and convenience. The Prism headset is designed to be comfortable for prolonged wear, making it a practical choice for both personal and professional use. However, AR is still in the early stages of development, hence the testing and validation of the proposed solutions can take considerable time and cost prohibitive.

“In an ideal world, we should be able to leave prototypes for customers so that we can see what it’s like in their daily lives, as this provides us with the most valuable insights,” – says Haley Harrington, product design engineer at Mira.

This dedication has led the company to explore new additive techniques to dynamically develop the product based on the feedback gained.

Solution: Supply chain improvement and flexibility with Multi Jet Fusion

Multi Jet Fusion, with its high precision and customisation capabilities, has become an ideal ally of Mira’s mission. The collaboration enabled the creation of lightweight yet robust components, improving both the aesthetics and functionality of subsequent versions of the headset. MJF offered a number of advantages, including complex design capabilities, the ability to iterate quickly, obtain parts at low cost and high quality in a relatively short period of time.

“MJF allows us to produce complete, functional, high-quality devices that we can get into the hands of our customers,” – Harrington says. “Through this process we are able to get continuous feedback and make significant improvements to our design.”

Components printed through Multi Jet Fusion technology to create the Prism headset prototypes.

Components printed through Multi Jet Fusion technology to create the Prism headset prototypes.

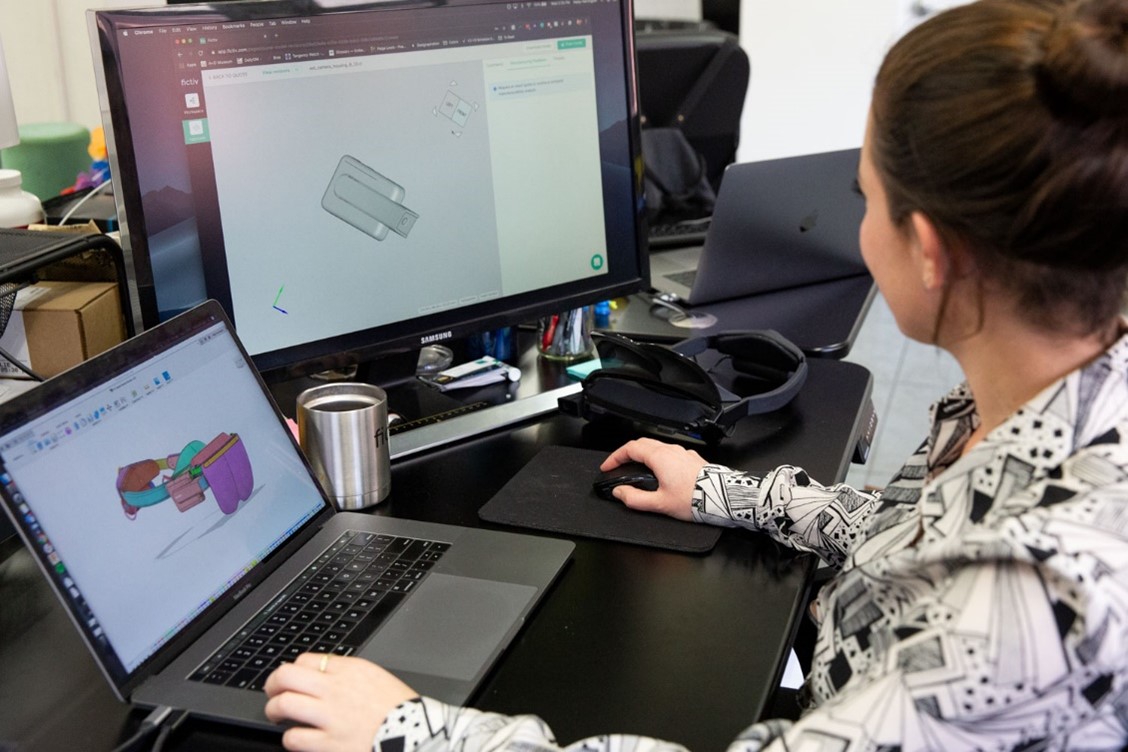

The process of designing headset parts before they are printed.

The process of designing headset parts before they are printed.

What happened to the Mira company next?

Just a day after Apple unveiled Vision Pro, its $3499 mixed reality (VR and AR) headset, news broke of the acquisition of Mira by the company with the bitten apple logo.

An equally big deal, and one to be proud of, is the agreement with Nintendo World, which uses the Mario Kart ride headsets at its theme parks in Japan and Universal Studios in Los Angeles. To enhance the ride experience the AR headsets display virtual characters and objects from the game.

The Apple Vision Pro headset, shown in a pre-release video announcement.

The Apple Vision Pro headset, shown in a pre-release video announcement.

A headset from Mira worn while driving Mario Kart in Nintendo World.

A headset from Mira worn while driving Mario Kart in Nintendo World.

So it’s safe to say that the use of Multi Jet Fusion 3D printing technology has undoubtedly contributed to such rapid success for Mira, which has partnered with some of the biggest electronic giants on the market in just seven years since the start-up was founded. And this is just the beginning.

Karolina Urbaniak