Help your imagination become reality with MJF

3D printing is certainly not only bringing a revolution to the lives of adults, but also to the lives of children. Due to the wide variety of toys and their widespread use of plastic on the market, we can expect to see more and more products produced using Multi Jet Fusion technology, which is ideal for reproducing complex shapes in a fast and highly accurate manner.

Print your clone

Unique customer, unique doll – this is the idea behind Spanish doll manufacturer LookReal. The team set themselves the goal of creating dolls that were each unique. “To achieve this, we had to go beyond painting and decorating. People have different facial features and we wanted to capture them in real life. We needed a way to create each face independently,” says LookReal CEO Philippe Joubert.

A LookReal production doll created in the likeness of the client.

A LookReal production doll created in the likeness of the client.

Personalising each doll to such an advanced level, while possible, would consume a lot of time, thus becoming uneconomic. LookReal streamlined and automated the entire process by using digital images of the face in special software and then recreating the object in three-dimensional space using an HP Multi Jet Fusion printer.

The material used to print the dolls is highly receptive to different types of paint, so it is possible to paint the dolls in any colour. What’s more, in the 8-10 hours it would take a standard 3D printer to print one part, the HP Multi Jet Fusion printer prints 250 parts.

The various stages in the production of personalised dolls.

The various stages in the production of personalised dolls.

The superpower of 3D printing

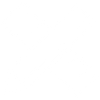

Another example of tailoring a toy individually to a child is the initiative of the hospital in Sant Joan de Deu in Barcelona – ‘La Brigada de los Valientes’, or the Brave Brigade. This is a project in which little patients had the opportunity to create their own superhero figures thanks to the great power of MJF. The creative process could not fail to include professionals in bringing imagination to life on paper, namely cartoonists from the comics industry who are known for their work for such renowned publishers as DC Comics and Marvel. Over the course of several sessions, the children, together with the illustrators and the scriptwriter, created a film consisting of digital sketches of six characters that they created together.

Six superheroes created during the project: Reina Alada, Strongess, Repair-Man, Sparta XXIII, Supergarr, Dra. Gema.

Six superheroes created during the project: Reina Alada, Strongess, Repair-Man, Sparta XXIII, Supergarr, Dra. Gema.

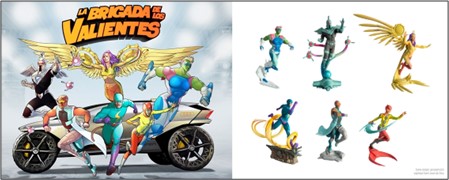

However, a problem arose during the task. One of the participating girls had visual difficulties, preventing her from seeing the 3D visualisation with the character she had designed. From there, the idea of printing a figure specifically for her was born, which then evolved into the broader concept of creating all six figures twice (two of each character) using Multi Jet Fusion technology. For this, an HP Jet Fusion 580 Color 3D printer was used, enabling the various elements of the superheroes to be coloured, which undoubtedly translated into spectacular final results. The painting was done using the ‘Polypaint’ technique, where each point on the model is assigned an RGB value in 8-bit format, and then the data stored in the structure is read out by the printer.

An excerpt from the design of the 3D model of the Sparta XXIII hero and the final version of the figure.

An excerpt from the design of the 3D model of the Sparta XXIII hero and the final version of the figure.

“The whole painting process is quite labour-intensive and we could perhaps even have done without it, but the final quality of the HP colour print is spectacular, offers an extraordinary level of detail and made it worthwhile,” – says a delighted Xan Elias Borras Borrell, the 3D sculptor taking part in the project.

Karolina Urbaniak