Revolution in Injection Mold Manufacturing: MJF Technology from HP at the Forefront

Revolutionary Multi Jet Fusion (MJF) technology from HP

Multi Jet Fusion (MJF) technology from HP is a revolutionary method for manufacturing plastic injection molds. MJF makes it possible to create injection molding dies with precise shapes and high quality, resulting in better performance of manufactured parts. Unlike classic injection mold manufacturing methods, such as CNC, mold manufacturing using MJF technology is economical and much faster. Until recently, additive methods were only used to create molds for prototype verification.

Manufacturing injection molds using MJF technology from HP

Classic molds for injection molding machines are mostly made of metals (aluminum, steel, etc.) using CNC and, through high investment costs, are only viable for mass production. Manufacturing injection molds using MJF technology is relatively fast and economical compared to traditional production methods. The technology also enables the production of more complex and precise injection molds, which translates into higher quality of manufactured parts.

Innovative applications of MJF technology from HP at Arcesso Dynamics and Eurecat

As a company specializing in polyurethane parts, Arcesso Dynamics is using HP MJF technology to produce injection molds with high quality finishes for industries such as furniture, medicine, electronics and others. Their goal is to replace current silicone molds with molds created using HP Multi Jet Fusion (MJF) technology and avoid the need for periodic replacement.

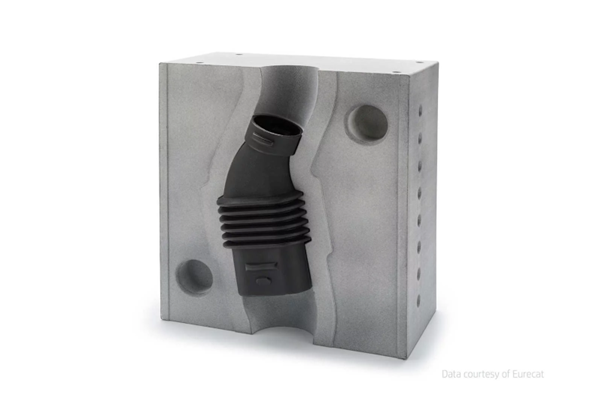

Eurecat, a leader in innovative technologies and services, has also applied Multi Jet Fusion (MJF) technology from HP in the manufacturing process of injection mold dies, allowing it to increase productivity and reduce production costs. Thanks to this cutting-edge technology, Eurecat is able to create dies of high quality, yet in less time and at a lower cost than traditional production methods. Using MJF, Eurecat is able to reduce the production time for injection mold dies by more than 30%, allowing it to bring products to market faster. Compared to traditional die manufacturing methods, which can require a lengthy machining process, MJF technology allows dies to be created more automatically and without the need for tools.

Rapid development of MJF technology in injection mold manufacturing

MJF technology significantly reduces mold production time, resulting in faster time to market for products. The production of machined molds usually takes many weeks or months, while molds produced with MJF technology are ready in a matter of days. As a result, Multi Jet Fusion technology is becoming increasingly popular among companies producing small and medium runs of plastic parts.

Kinga Sekuła, M.Sc.