Metals in 3D printing

The intensive development of additive manufacturing technologies requires new powder materials, especially when it comes to metals and metal alloys. Thanks to our close cooperation with the Wroclaw University of Technology, we are opening a new path by betting on the production of metal powders by the innovative method of ultrasonic atomization.

Prototype of ULTRAMIZER device during operation

Prototype of ULTRAMIZER device during operation

Ultrasonic atomization

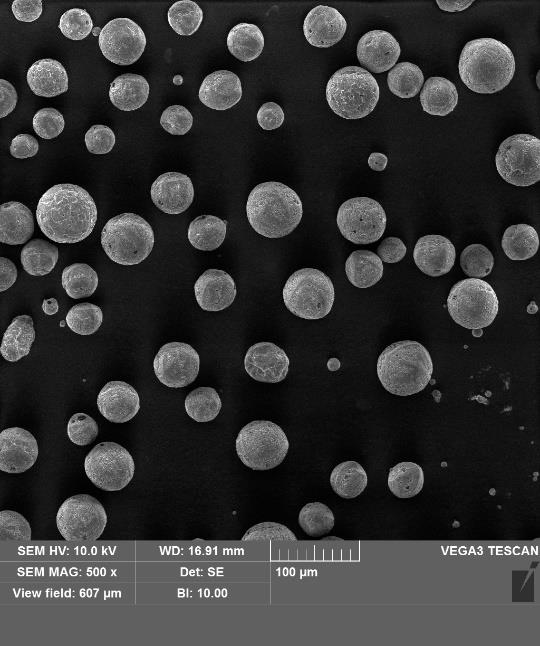

Ultrasonic atomization is a new method, and unlike common manufacturing methods such as water or gas atomization, the medium used to break liquid metal into fine droplets is ultrasonic waves. This primarily results in the ability to produce powders with a very narrow distribution and a dedicated size. In addition, powders obtained in this way have a high sphericity coefficient and extremely low porosity.

The very idea of using ultrasonic waves for atomization is known from medicine (e.g., ultrasonic nebulizers) or household applications (e.g., ultrasonic humidifiers), among others. High-frequency vibrations enable efficient fragmentation of liquids in ultrafast time. This very effect is used in the prototype ULTRAMIZER technology developed at the Wrocław University of Technology under the LIDER project funded by the National Center for Research and Development.

Phenomenon of atomization of water droplets with ultrasonic waves at a frequency of about 70 kHz.

Powder samples

3D Center is a partner in the development of this technology and invites you to cooperate, especially those interested in prototyping, the search for new materials, or the development of this technology itself in cooperation with 3D Center and Wroclaw University of Technology. Making small batches of powders with dedicated characteristics has never been easier. If you are interested in cooperation, we invite you to contact us.

Spherical austenitic steel powder produced by ULTRAMIZER technology